Description

NFC apple juice refers to apple juice that is directly extracted from fresh apples without undergoing concentration and reconstitution processes. It is pasteurized at low temperatures and then bottled, maximizing the retention of the natural flavor, vitamins, and minerals found in apples. Compared to traditional concentrated and reconstituted juices, NFC apple juice has a taste that is closer to that of fresh fruit, making it highly popular in the premium juice market. To meet the production needs of juice processing companies for high-quality apple juice, we have launched this NFC apple juice making equipment, which can be customized to meet customers’ production capacity requirements.

The Main Advantages of NFC Apple Juice Include:

- No added sugar, preservatives or coloring.

- Nutritional ingredients are intact, rich in vitamin C and natural antioxidants.

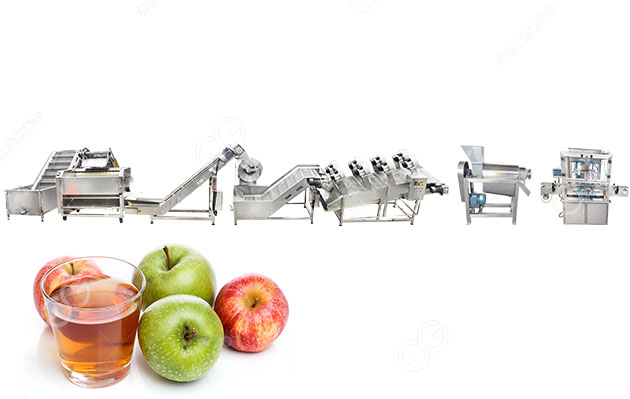

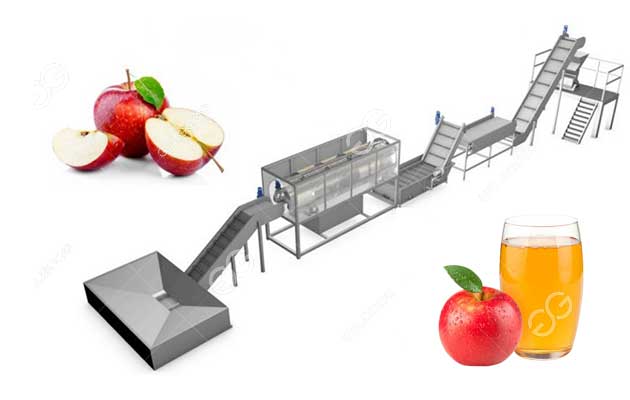

NFC Apple Juice Making Process:

- Raw material selection and pretreatment: Select fresh apples and remove rotten and diseased apples.

- Washing: The apples are tumbled in the washing machine with bubbles, washed with water and brushed with brushes to ensure the surface is clean.

- Crushing and juicing: Use a crusher to crush the apples, and then use a press to physically squeeze the juice to maximize the juice yield.

- Coarse filtration and fine filtration: Freshly squeezed apple juice is first passed through a coarse filter to remove large particles of impurities, then clarified through a filtration system.

- Degassing and pasteurization: A vacuum degassing device is used to remove oxygen from the juice to prevent oxidation and discoloration; the juice is then briefly heated in a pasteurizer to sterilize it.

- Aseptic filling and refrigeration: The sterilized juice is packaged in bottles, boxes, or bags using an aseptic filling machine and stored in a low-temperature environment of 2–8°C to extend its shelf life.

Industrial Apple Juice Machine Features:

- Highly automated: Fully automated control from feeding to filling completion, reducing manual operations and improving efficiency.

- Customized design: Flexible configuration of apple juice making equipment combinations based on actual production capacity (e.g., 500 kg/hour to 10 tons/hour) to meet the needs of different production scales.

- High-Quality Materials: All components in contact with juice are made from food-grade 304 or 316 stainless steel, compliant with HACCP and GMP hygiene standards.

- High juice yield and low loss: The industrial apple juice machine uses advanced belt presses and efficient filtration systems to ensure a juice yield of up to 75%-85%.

The apple juice making process generates large amounts of pomace and scrap. Effective utilization of these by-products can not only reduce processing costs, but also expand product lines and improve overall economic efficiency.

If you would like more information about apple juice making equipment, please contact us.

Reviews

There are no reviews yet.