Description

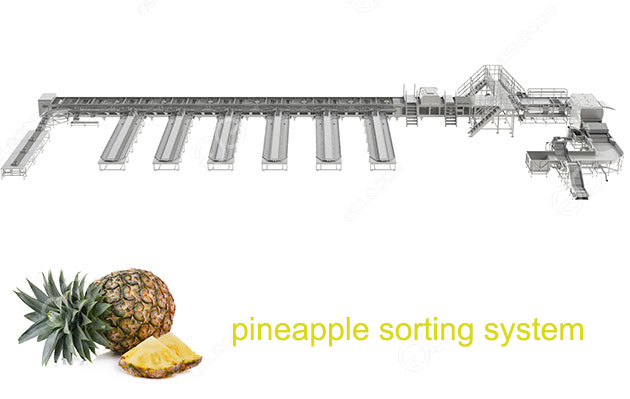

Pineapple sorting machine helps pineapple planting and processing enterprises achieve standardized and large-scale production through a high-precision, high-efficiency, and intelligent grading method.

Purpose of Pineapple Grading:

- Enhance product image: Precise sorting groups pineapples with similar appearance and quality into the same grade, improving the overall product image.

- Increase economic benefits: Higher-grade pineapples can enter the high-end market, achieving higher selling prices and thus increasing company profits.

Pineapple Sorting Indicators:

Pineapple grading machine typically employs various grading standards based on the characteristics of pineapples and customer needs, enabling multi-dimensional detection and automated sorting. It mainly includes:

- Weight grading: The pineapple sorting machine is equipped with a high-precision weighing system that automatically identifies the weight of each pineapple through dynamic weighing technology, achieving accurate grading. Suitable for export and quantitative packaging scenarios.

- Size grading: The diameter and height of the pineapple are measured using an optical measurement system to classify pineapple of different sizes.

- Sugar content grading: Non-destructive sugar content measurement is used to sort pineapples with high sweetness and good taste for fresh consumption or the high-end market.

- Color grading: High-definition camera system analyzes the peel color to distinguish ripeness levels. Fruits with a uniform, golden-yellow color generally indicate superior quality.

These sorting indicators can be used individually or in combination to meet the customized needs of different markets and customers.

Pineapple Grading Machine Features:

- High sorting speed and efficiency: The pineapple sorting machine adopts a high-speed conveyor and multi-channel detection design, capable of sorting 1-10 tons of pineapples per hour, greatly improving production efficiency.

- Low damage rate, protecting the fruit: The sorting machine has a reasonable structural design, using flexible conveyors and buffer devices to avoid collisions and compression of pineapples during the sorting process, ensuring the peel remains intact and the flesh undamaged.

- Small grading error and high precision: This pineapple grading machine achieves accurate detection through high-sensitivity sensors and intelligent algorithms, with grading errors typically controlled within ±1%.

- High return on investment: Compared to manual sorting, automated equipment requires only a one-time investment and can be used long-term, saving labor costs, increasing product added value, and achieving rapid return on investment.

Applications:

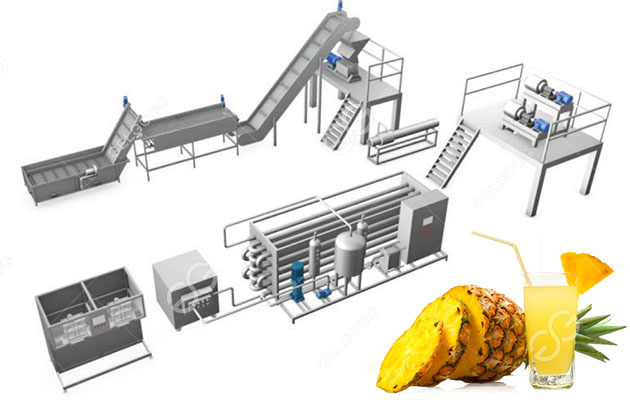

Pineapple sorting machine with conveyor belt is highly versatile and suitable for sorting various fruits. Besides pineapples, it is also widely used for: mangoes, avocados, dragon fruit, oranges, grapefruits, passion fruit, etc.

Reviews

There are no reviews yet.