Description

Basil pesto sauce is a very popular sauce, mainly used in pasta, pizza, sandwiches and other dishes. In industrial production, the processing of basil pesto is mainly carried out by automated pesto sauce production line to ensure the flavor, hygiene and shelf life of the product.

Raw material preparation:

- Fresh basil leaves

Choose green basil leaves that are free of pests and diseases.

After preliminary selection, use a bubble washing machine to clean and remove mud and impurities.

Use air drying or centrifugal drying equipment to dehydrate to prevent excess water from affecting flavor and preservation.

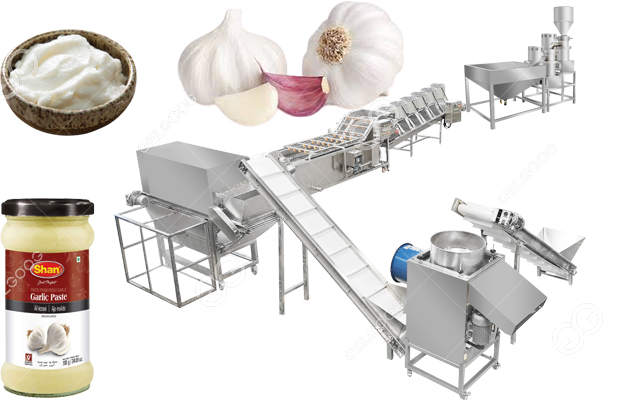

- Garlic

Separating the garlic into cloves, peel it, and wash it for later use.

- Preparation of auxiliary materials

Pine nuts: roast them in advance for later use. The raw materials can be changed according to different recipes. Some factories will use cashew nuts.

Olive oil: high-quality cold-pressed olive oil is an important source of flavor and texture.

Main Production Process of Basil Sauce Production Line:

- Raw material feeding

Weigh basil leaves, pine nuts, cheese powder, garlic, etc. according to the formula and add them to the grinder through the automatic feeding device.

- Grinding and mixing

Use a colloid mill for high-speed shear mixing to make the raw materials into a uniform and delicate green sauce.

- Adding oil

During the process of beating the sauce, olive oil is gradually added to obtain the ideal texture and aroma.

- Pasteurization

Basil sauce that needs to be stored at room temperature may be low-temperature pasteurized, usually at a temperature not exceeding 85°C, to maintain the green color and flavor.

- Filling

Use an automatic basil sauce filling machine to fill the basil sauce into glass bottles or PET bottles. Automatic filling is fast and can be combined with automatic conveyor belt operations.

Notes for Using Pesto Sauce Production Line:

- Control temperature: Do not overheat during the process of making sauce to prevent the basil from turning black.

- Prevent oxidation: Try to avoid contact with air throughout the process, and use nitrogen filling or vacuum packaging.

- Stable material ratio: Ensure that the taste of each batch is consistent.

- Sanitary design: the basil sauce production line and pipelines must be easy to clean to prevent cross contamination.

The above is the main process of basil sauce production. According to different formulas, we will provide customized solutions to achieve precise production.

Reviews

There are no reviews yet.