Description

High output mango juice production line equipment uses mango as raw material. Supplemented with certain white sugar, stabilizers, and other additives, a nutritious mango juice drink with unique flavor is formulated. Mango drinks are produced through processes such as mango cleaning, mango peeling and core removal, mango beating, mango juice beverage blending, sterilization, mango beverage filling machine, and packaging.

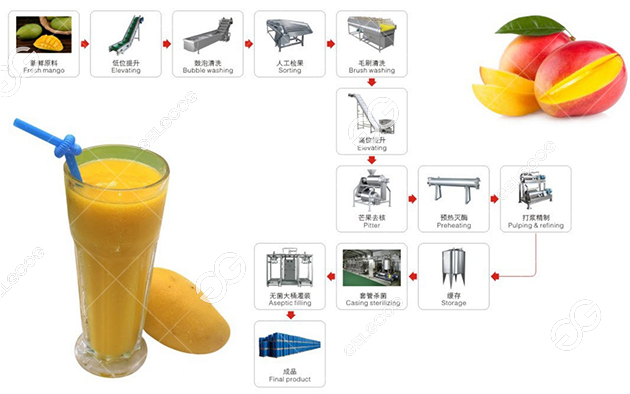

Process flow of mango juice production line

One. Selection

Selection of equipment raw materials for high output mango juice production line. Choose fresh fruits that are fully mature, fresh, good flavor, rich in juice, and disease-free. Those with insufficient maturity must be post-ripened.

Two. Raw material pretreatment

- Cleaning. After selecting the raw materials, rinse them with clean water to remove the hairs and rinse them in a 1% hydrochloric acid solution or detergent solution to remove residual pesticides, then rinse in clean water and drain.

- Mango peeling and pitting is processed with a special peeling and pitting machine for mangoes, and then preheated to kill enzyme

Three. Heating and beating the mango pulp.

The mango pulp is heated at 90C-95C for 3-5 minutes to promote softening. The pulp is beaten by a beater with an aperture of 0.5 mm to remove the peel.

Four, Mango beverage preparation

The fruit pulp after the previous step needs to be adjusted in order to increase the flavor. Add ingredients such as sugar, citric acid and L-ascorbic acid when adjusting. The ratio is 100 kg of peach pulp, 80 kg of 27% sugar solution, 0.45 kg of citric acid, 0.07-0.2 kg of L-ascorbic acid.

Five. Homogeneous degassing of mango beverage

- Homogenization is to split the suspended pulp particles of the juice into smaller particles and evenly disperse them in the juice to increase the stability of the juice and prevent delamination. The method of homogenization is to pass the coarsely filtered juice through a high-pressure homogenizer, so that the pulp particles and colloidal substances in the juice pass through small holes with a diameter of 0.002-0.003 mm under high pressure to become finer particles. Generally, a homogenizer of 130-160 kg/cm² is used in production.

- In addition, colloid mill can be used for homogenization. When the juice flows through the slit with a gap of 0.05-0.075 mm in the colloid mill, the pulp particles in the juice are impacted and rubbed by the strong centrifugal force, so as to achieve the goal of homogenization.

- The fruit enters oxygen, nitrogen, carbon dioxide and other gases during juice extraction. Among them, nitrogen can cause oxidation of vitamin C and pigments. Therefore, it must be degassed.

Six. Mango juice filling machine

The mango juice produced by the high output mango juice production line is heated to 95″C, maintained for 1 minute, and filled immediately while hot, using hot filling.

Seven, Sealed cooling

Tighten the cap, and turn the can upside down for—minutes. After sealing, it will be quickly cooled in sections to about 38℃, and then stored in the warehouse. The finished fruit tea of qualified quality is pink or yellow-brown, it is allowed to be dark red, the juice is uniformly turbid, and there will be particulate precipitation after long-term standing, with a peach juice flavor, no peculiar smell, and soluble solids of 10%-14%.