Description

Pineapples are typically grown and harvested in open-air environments, and during growth, transportation, and storage, their peels easily accumulate large amounts of soil and dust. Furthermore, the surface structure of pineapple peels is complex and uneven. If not thoroughly cleaned, this can affect not only the appearance but also the quality. Whether sold as fresh fruit or used for further processing (such as canned pineapple, pineapple juice, frozen pineapple, etc.), pineapples must be thoroughly cleaned using professional pineapple washing machine.

This pineapple cleaning machine utilizes a combination of soft brush cleaning and high-pressure water spraying. During the cleaning process, pineapples are conveyed into the cleaning area, where the brushes make full contact with the pineapple surface, reaching into the crevices and grooves of the peel to effectively remove attached dirt and impurities without damaging the fruit.

Simultaneously, a water spraying device above the pineapple washing machine continuously sprays clean water, thoroughly rinsing the pineapples from all angles. The sprayed water not only washes away the impurities removed by the brushes but also further enhances the thoroughness of the cleaning, resulting in a cleaner, more natural, and residue-free pineapple surface.

Pineapple Cleaning Machine Features:

- The cleaningmachine is made of food-grade stainless steel.

The main body of the pineapple washing machine is made of SUS304 stainless steel, which is corrosion-resistant, acid and alkali resistant, meets food processing hygiene standards, has a long service life, and is easy to clean and maintain.

- Adjustable brush speed to suit different needs

The brushes are driven by independent motors, and their rotation speed can be adjusted according to the size of the pineapple and the degree of surface cleanliness. This ensures effective cleaning while avoiding unnecessary friction on the fruit.

- Water-saving design, reducing operating costs

The spray water system allows for water recycling (optional filtration device), effectively reducing water consumption while ensuring cleaning effectiveness, meeting the energy-saving and environmentally friendly requirements of modern factories.

Pineapples processed by the pineapple cleaning machine have a clean surface and neat appearance, and can be directly used in various processing stages, making them suitable for a wide range of applications.

① After cleaning and air drying, the pineapples are graded and packaged for sale as fresh fruit.

After cleaning, the pineapples are transferred to a air drying machine to remove surface moisture. They are then graded and packaged according to size, weight, or appearance using grading equipment, and sold directly as fresh fruit in the market.

② Connected to peeling, coring, and cutting equipment, the production of canned pineapple begins.

In the canned pineapple production line, cleaning is the first step in standardized processing. After cleaning, the pineapples can be directly fed into peeling, coring, and cutting machines for further processing into pineapple rings, chunks, or dices, followed by canning, syrup filling, and sterilization.

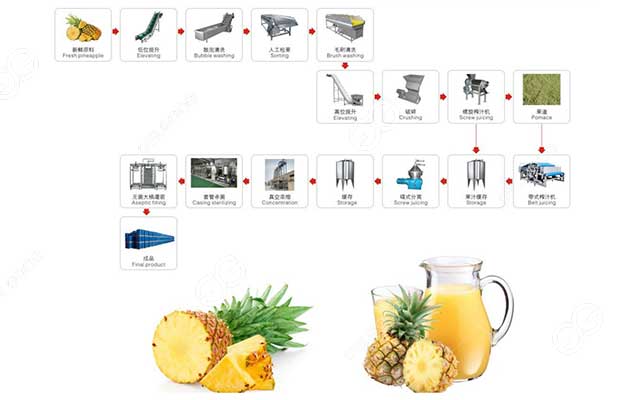

③ Connecting to the juice production line, for pineapple juice production:

In the production of pineapple juice or mixed fruit juices, the cleaned pineapples can be directly fed into crushing, juicing, or pulping equipment. A clean fruit peel surface effectively reduces impurities entering the juice, improving the purity and taste stability of the juice.

Reviews

There are no reviews yet.