The tomato paste production line turkey originated from Turkey’s climate is conducive to the cultivation of vegetables. Turkey’s tomato production accounts for 38% of Turkey’s total vegetable production. The greenhouses are used to grow tomatoes in an area of about 25,000 acres. According to relevant statistics, Turkey will become the third largest tomato producer in the world. 70% of Turkish tomatoes are for local consumption, and the other 30% are processed.

30% of Turkey’s tomatoes are used for tomato processing, and are made into tomato products such as tomato sauce, tomato juice, tomato sauce, canned tomato, etc. We are professionals tomato processing plant manufacturers,we can provide you with the corresponding tomato processing machinery according to your final product. The mainstream processing method for tomatoes in the Turkish market is still processed into tomato paste.

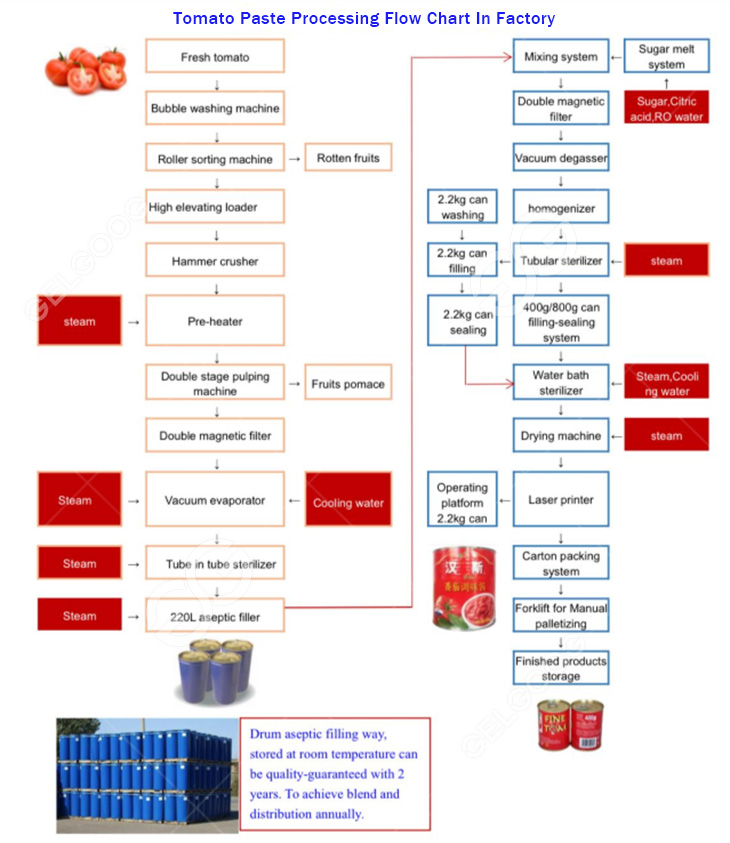

The Turkey’s tomato paste manufacturing process mainly includes washing, picking, crushing, preheating, beating, concentration, degassing, homogenization, sterilization, and filling of fresh tomatoes.

Pre-treatment of tomatoes: The storage of tomatoes generally adopts wet storage in an open-air reinforced concrete rectangular pool with flow ditch. The storage period does not exceed 24 hours.

Tomatoes are transported into the production workshop by hydraulic conveying ditch, which can remove the grass, leaves and other sundries mixed into the tomato raw materials. It can also wash away the soil, sand, microorganisms and pesticides attached to the surface of the tomatoes. Then enter the washing machine and strengthen the washing.

Tomatoes used in the sauce are mature and intact fruits, and the tomatoes must be eliminated from rotten, rot, and pests.

Tomato broken

The purpose of crushing tomatoes is for better beating and improving pulp yield. Tomato crushing is divided into thermal crushing process and cold crushing process. The crushing method used has a certain relationship with the quality of the raw materials and the quality requirements of the product.

Tomato preheating

The tomato needs to be pre-heated before beating. Its purpose is mainly to inhibit the activity of pectinase, prevent the product from producing juice separation; soften the broken pulp. It is beneficial to the beating well to reduce the loss during beating and increase the viscosity of the product: eliminate the fruit Interstitial space and air in the pulp meter. Conducive to the preservation of vitamin C and avoid foaming during heating and concentration.

Tomato Pulping and refining

Tomato pulping and refining is one of the important processes of tomato paste processing. Tomato beating is to remove impurities such as peels and seeds to obtain a uniform and delicate puree. The crushing tomato through the refiner completes the pulping and refining process at one time. The waste residue produced by the beating and refining is about 3% of the weight of the raw material. If the slag is too wet, the loss rate of the raw material will increase, and the pulping rate will be low; if the slag is too dry, the seeds will be squeezed by the scraper in the beating machine. Rubbing and breaking will affect the flavor and shape of the finished product. Therefore, the working parameters of the refiner should be adjusted during the production process. Generally, the slag should be taken and pinched in the palm at any time during the beating. It is advisable to drip with juice-free water and have juice on the palm after relaxing.

The pulping and refining machine currently used is generally composed of two or three channels, and the screen mesh holes are 0.8, 0.6, and 0.4mm respectively.

Evaporative concentration

Tomato puree needs to be concentrated nearly six times to make tomato paste. At present, most of the equipment used is vacuum evaporation and concentration.

Three-effect or four-effect forced circulation tube evaporator is often used. Multi-effect forced circulation tube evaporator is suitable for the evaporation and concentration of relatively viscous and poorly fluid materials.

The multi-effect evaporator only uses raw steam for heating. The other effects are heated by the steam of the previous effect in turn, and the raw steam consumption is only 1/3-1,/4 of the single-tech evaporator, and the energy-saving effect is obvious.

Homogeneous

The concentrated tomato sauce is homogenized by a homogenizer. The sauce body is more uniform, fine, stable, and taste better.

Sterilization

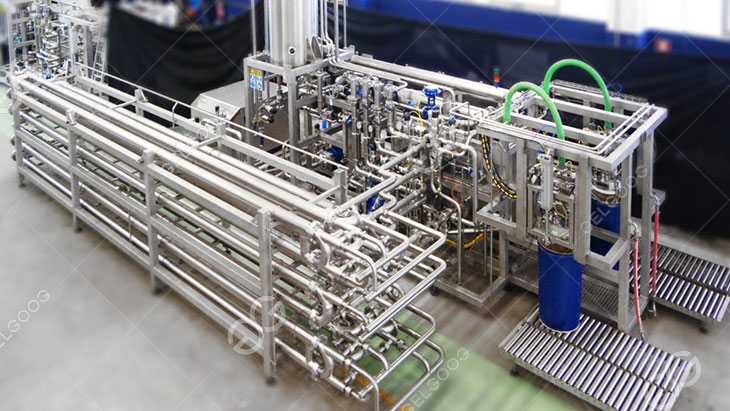

Pasteurization (110-115°C), cooling (35-37°C) 8 filling

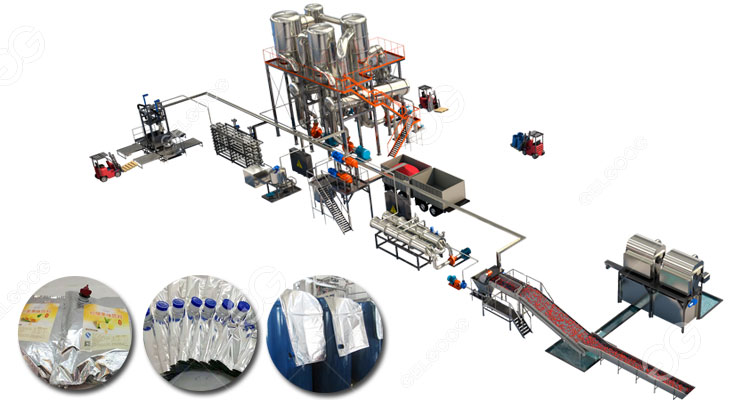

The needs of the international market are all aseptic packaging methods, that is, the tomato paste is packed into pre-sterilized packaging bags in an aseptic environment. The packaging form is aseptic bag in drum or bag in box. The product temperature after filling is low. Sterile and without losing the true colors. Keep the bag between the aseptic bag and the outer packaging iron drum or box. Prevent the tomato sauce bag from causing losses during transportation and handling. This type of packaging allows the product to be stored for two years at room temperature without losing its quality, color and taste.

The 220L aseptic vat filled tomato sauce can be used for export, and is usually subcontracted by the Turks and sold to small local tomato processing plants for the production of tomato sauce. Do you also want to start a tomato paste processing business in Turkey? For any questions about tomato processing, you are welcome to contact us online at any time, and we will provide you with customized tomato processing machinery according to your specific needs!!!