Description

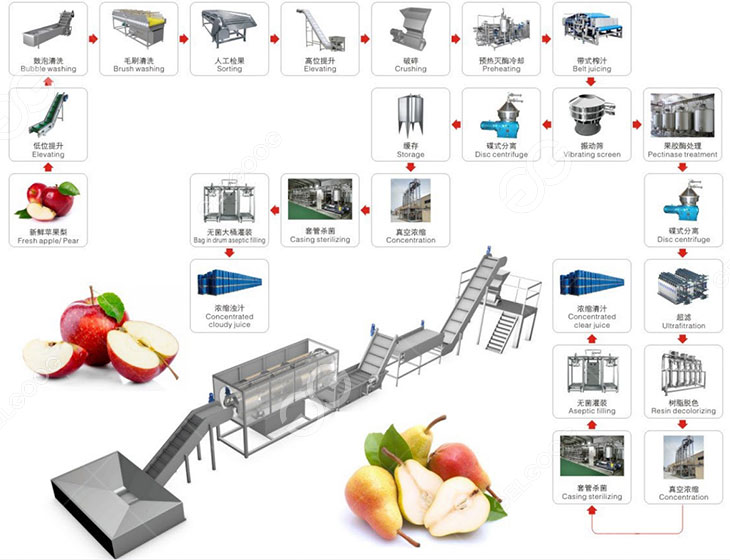

The apple juice processing line is suitable for the apple/pear juice industry. The apple/pear fruit juice manufacturing process mainly includes apple pear sorting, crushing, washing, juice extraction, clarification/homogenization, mixing, sterilization, filling and cooling. It can process 500kg-4T apple/pear per hour, and can produce apple/pear clear juice, turbid juice or concentrated juice according to needs.

Apple/pear picking

This process is completed by the fruit sorter. The purpose is to eliminate rotten, diseased, and mechanically damaged apples, and to select mature, complete, and high-quality apples/pears as raw materials to ensure the quality of apple juice.

Some apples/pears have disease or mechanical damage in some parts, which can be trimmed with a stainless steel knife. In addition, the stem and core should be removed before juicing.

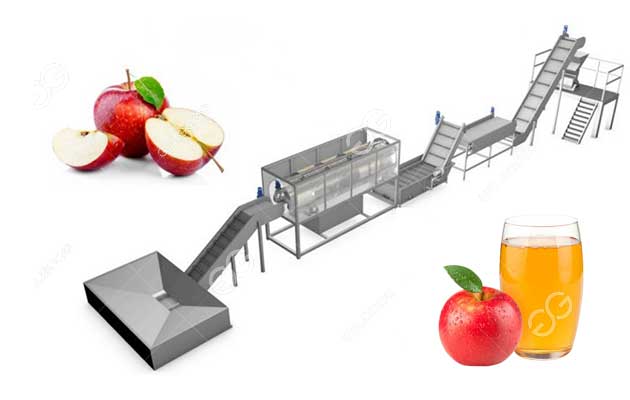

Apple/pear cleaning

Clean and fresh apples/pear are very important for making delicious and healthy juice, so apple/pear washing machine is an essential equipment to ensure apple hygiene. Apple bubble cleaning machine is mainly composed of blower, water tank, drum, spray pipe, hopper, etc. It is a special machine based on the strong stirring motion of the high-pressure fan, wind-powered cargo pump and the water pressure, so that the apple/pear in the water are poured back and the cleaning efficiency is improved, so as to achieve the purpose of cleaning the apple/pear.

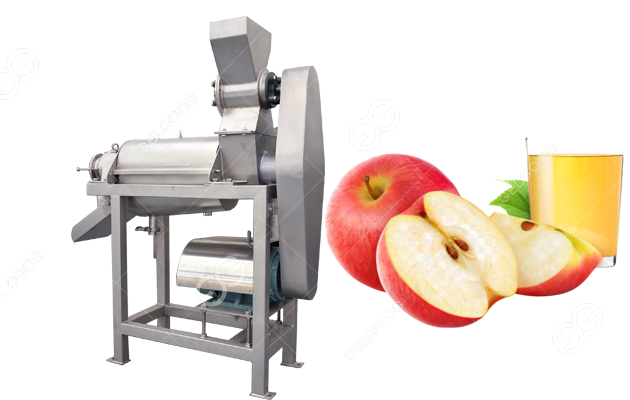

Apple/pear squeezed juice

Use a stainless steel crusher to crush the apple/pear into pieces. These apple/pear pieces are then fed into the screw juicer all at once. The screw juicer is a continuous operation slag juice separation equipment used for squeezing out liquid from organic materials and separating slag from inorganic materials. This equipment has high strength, large bearing pressure, no deformation, no blocking, corrosion resistance It is wear-resistant, non-slip, low failure rate, convenient maintenance, long service life, and extremely high juice yield and dehydration rate.

Pasteurized Apple/Pear Juice

The clear apple juice is processed by a tube or plate type sterilization machine according to the filling method. If we use hot filling, then we can use a plate pasteurizer. The sterilization process is 90-95°C for 15 seconds; if sterile washing is used, a tube sterilizer is used. The sterilization process is 4-6 seconds at 135-137°C.

Homogenization of cloudy juice

Homogenization is the process of making cloudy juice. It is carried out under a pressure of 100-120kg/cm2. It is recommended to degas the apple juice with a vacuum of 600mmHg.

Here is the apple/pear juice processing flow chart

Clarified juice

Clarification and filtration is the process of making clear apple juice. The extracted juice is first clarified with an enzyme preparation method, and then filtered with a beverage filter. Clarified apple juice should be clear and transparent, otherwise it needs to be filtered again.

The pH value of apple juice is usually 3.2-4.0, and the most favorable pH value for pectinase is 3.5-5.0. This means that pectinase works well in apple juice, and there is no need to adjust the pH. But sometimes the PH value of apple juice exceeds the requirement of pectinase, and the pH value needs to be adjusted according to different apple juice. Do not use alkali for this operation, otherwise it will affect the quality of apple juice.

The clarification effect is affected by temperature. Increasing the temperature without affecting the enzyme activity can improve the clarification effect and shorten the clarification time. Temperature 34-40, pH 3.5, add 0.025% pectinase and 0.005% gelatin, the apple juice will clarify after 30-60 minutes. When the temperature and pH are the same, the clarification time is directly proportional to the enzyme concentration. 0.005% gelatin can shorten the clarification time by 50%.

If necessary, the apple/pear juice can be concentrated. The concentration system plays a vital role in the apple/pear juice production line. The small volume of concentrated apple/pear juice can save packaging and transportation costs. Vacuum degasser and falling film evaporator can be used in this process, but in general, 100% pure apple/pear juice is best, so you can choose whether you need to concentrate according to your actual situation.

Apple/Pear Juice Filling Machine

There are two filling methods, one is hot filling and the other is aseptic filling. The aseptic filling machine is usually connected with a tube-type ultra-high temperature sterilizer and filled into aseptic bags and packaging.

Features of our apple/pear juice processing line

1. The automatic disinfectant concentration control system can effectively ensure the sterilization effect and control the disinfection residue.

2. The high-efficiency pulverizer improves the high juice yield of apples and pears.

3. Adopt high-efficiency belt juicer to improve the efficiency and rate of juice extraction.

4. Low-temperature vacuum evaporation greatly reduces the loss of apple/pear flavor and nutrients.

5. Tubular UHT sterilizer and aseptic filling machine can isolate bacterial contamination, ensure food safety, and extend product shelf life.

6. Complete production, CIP system can be configured to reduce labor intensity and ensure high level of hygiene.

Apples/pears are known as the most nutritious fruits, containing a variety of vitamins, minerals and sugars. Regularly eating apples/pears helps to enhance people’s memory and intelligence, as well as improve the respiratory system and protect us from smoke pollution. In addition to eating apples/pears directly, we usually process apples/pears into apple/pear juice and apple/pear jam. In recent years, apple/pear juice processing has become a prominent industry in countries rich in apple/pears in the world. More and more people enter the apple/pear juice industry. If you want to get more profits, choose professional apples/pears. The supplier of the juice processing line is very important.

Why choose to cooperate with us

Turnkey project, including selection, design, installation, training, etc.

Simple operation, good stability, high flavor and color retention of apple/pear juice.

Processing 0.5-4 tons of raw apple/pear per hour.

Provide complete sets of apple processing machines and stand-alone machines.

If you have any questions about apple/pear processing, please feel free to contact us online!!

Reviews

There are no reviews yet.