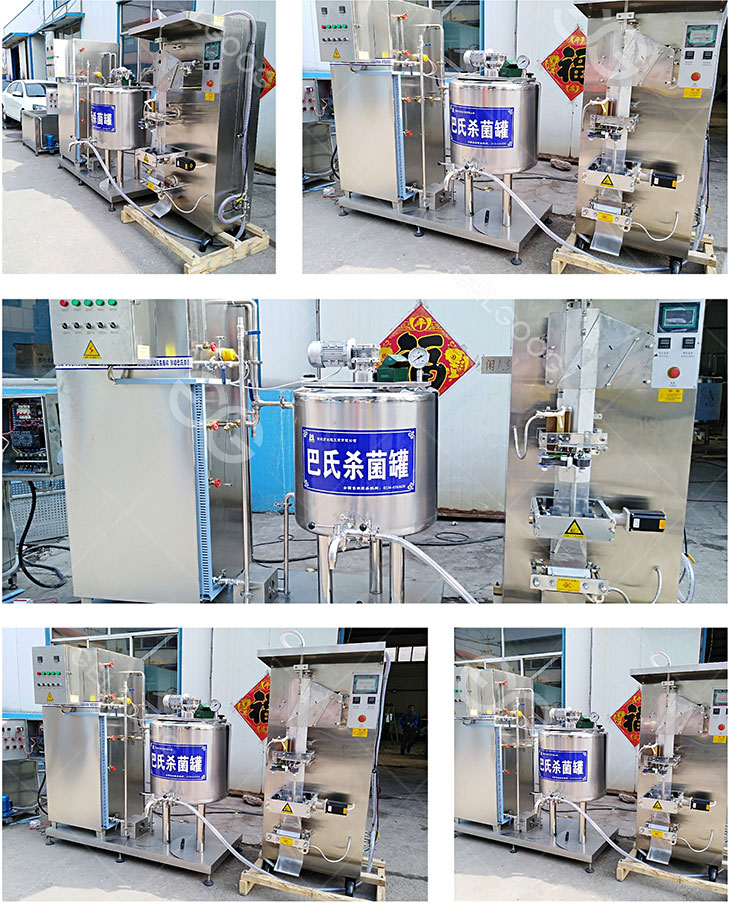

Description

The small scale juice pasteurization equipment uses pasteurization, which is a method of heating the fresh juice at a low temperature for half an hour to effectively remove harmful bacteria in the fresh juice.

The small scale juice pasteurization equipment uses a relatively low temperature (generally 60-99°C), and heats the juice within a specified time to achieve the purpose of killing microbial nutrients. It is a kind of disinfection that can achieve the purpose of disinfection without Ways to damage the quality of juice.

The small scale juice pasteurization equipment has two water tanks, a hot water tank and a cold water tank. There is a hydraulic gauge indicating the water level on the side, and an interface for connecting the refrigeration compressor.There is a refrigeration pipe at the interface. The upper part of the box has an electric control box for regulation.

Industrial Juice Pasteurizer working Process

Power on:

Turn on the power button

Pre-heating and pre-cooling:

A. The hot water tank heater starts to work, open the hot water circulation pipeline inlet and outlet valves], start the circulation pump for 60 seconds every 3 minutes

B. Turn on the refrigeration button to cool down the water in the cold water tank in advance

Sterilization:

A. After the water temperature of the hot water tank reaches the set temperature, add freshly squeezed juice.Open the hot water outlet valve and hot water return valve, and turn on the hot water circulating pump

B. When the juice temperature is below 50°C, start the blender for 3 seconds every 3/5 minutes;when the juice temperature is above 50°C, start the blender for 60 seconds every 2/3 minutes.

Cooling down:

A. Close the hot water outlet valve and hot water return valve, and open the tap water inlet and outlet valves_

B. After 3 minutes, close the hot water return valve and tap water inlet valve, and open the cold water outlet and cold water return valves

C. When the juice temperature is above 50C, start the agitator every 2/3 minutes for 60 seconds;when the juice temperature is below 50C, start the agitator every 3/5 minutes for 30 seconds.

Small Juice Pasteurizer Parameter

| Name | Model | Power(KW) | Dimension(MM) | Weight(KG) | sterilizing time | sterilizing temprature |

| Pasteurizing Machine |

GGJP50 | 4.5 | 650x650x1000 | 55 | 15seconds(adjustable) | 65-95℃(adjustable) |

| GGJP70 | 6.5 | 750x750x1200 | 70 | |||

| GGJP100 | 6.5/9.5(380V) | 850x850x1350 | 85 | |||

| GGJP150 | 6.5/9.5(380V) | 950x950x1500 | 100 | |||

| GGJP300 | 20(380V) | 1100x1200x1800 | 185 |

After low-temperature heat sterilization of the fresh juice, After the cold water tank is cooled down,we can drink the juice. Of course, for the processed fresh juice to be clean, hygienic and easy to store.We also provide a complete set of juice filling equipment for later storage and sales.This filling machine production efficiency: 2000 bags/hour,packing quality range: 200-500g/bag.

Because pasteurized fruit juice retains some microorganisms during its production process, its shelf life is short.It needs to be stored under refrigeration, which can be stored for 8 days.