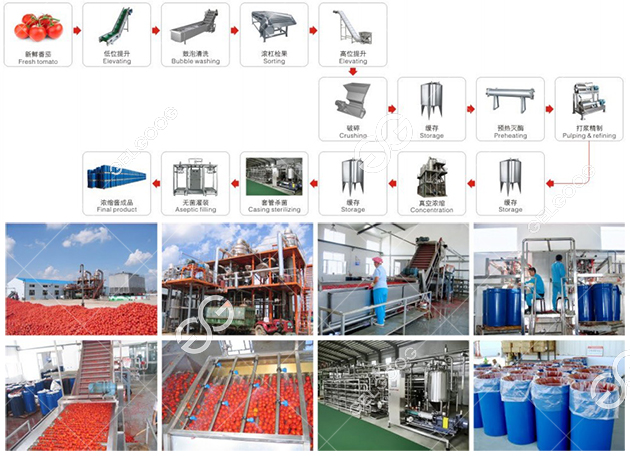

Introduction of the tomato paste production

Tomato paste is a concentrated product by the tomato paste production line. It uses ripe red tomatoes as raw materials. It is made by crushing, beating, peeling and seeding, canning, and sterilizing through the tomato paste production line.The finished product is a bright red sauce-like body with the unique flavor of tomato.

Tomato paste production line main features:

- The complete system has reasonable and beautiful design, stable operation, energy saving, and low steam consumption.

- The evaporator adopts a forced circulation type, which makes the tomato paste with high viscosity easy to flow and evaporate, and the concentration time is short.

- The evaporation temperature of the evaporator is low, the heat is fully utilized, the tomato sauce is heated gently, the heat is uniform in the tube, and the heat transfer coefficient is high.

- The condenser with special structure can operate normally under the condition of cooling water temperature of 30℃ or higher.

- Continuous feeding and discharging, material liquid level and required concentration can be controlled automatically.

Tomato Paste Production Line Operation points:

Step one: Cleaning

The tomatoes are uniformly placed in a container. Worker turns on the water tap. Tomatoes are driven by water to remove mixed impurities.

Step 2: Washing :

Plenty of fresh tomatoes enter the washing machine. The washing machine uses a bubble design to reduce the impact of tomatoes. Keep the tomatoes intact.

Step 3: Picking

After the cleaning is completed, the workers will pick out the bad tomatoes in time to avoid going to the next process.

After the tomato sauce has been cleaned, the tomato sauce comes to the sauce.

Step 4: Crushing

Before beating, we need to process the tomatoes in advance. Crush the tomatoes with the help of a coarse shredder.

Step 5: Preheating

Made of stainless steel 304, used for pre-heating inactivation of crushed tomato particles. It can protect the color and taste, and improve the pulping rate.

Step 6: Pulping

The kneaded tomato will automatically filter out the coarse and hard substances such as tomato skin and seeds by the ketchup equipment.

Step 7: Canning

The canning step, that is, filling the ketchup into a jar. Good canning preserves ketchup more. Extend the shelf life of ketchup.

After the ketchup is packed, it comes to the sealing step. One in and one out, the production is complete.

Step 8: Metal Detection

The contactor on the assembly line mainly tests whether the bottle is filled with ketchup, because in the factory production, if there is a mechanical failure resulting in missed installation, it is difficult for personnel to find, and it can only be detected by such a contactor. The yellow component next to the assembly line is a proximity switch that detects the passage of the tomato can.

Step 9: Packaging

Packing specifications are every six barrels, and every six barrels are neatly arranged. The packaging machine will automatically wrap the plastic packaging around the tomato bucket ~ At this time, it will pass through the high temperature area.

Step 10: Labeling

After passing through the high temperature zone, the plastic has been attached to the ketchup can. This is followed by an automatic labeling machine to label the passing tomato package. That’s it for ketchup.