Description

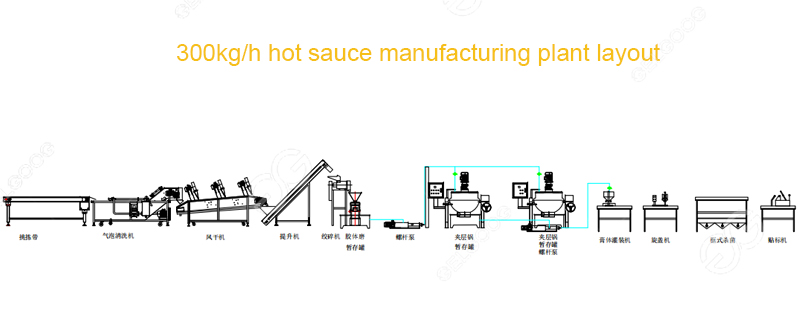

The hot sauce manufacturing plant designed to streamline the manufacturing process while maintaining the integrity and flavor of your signature sauces.

Crafted with precision engineering and advanced technology, the hot sauce making equipment offers unmatched reliability and performance. From raw ingredients to bottled perfection, every step of the process is seamlessly automated, reducing labor costs and minimizing human error.

Hot Sauce Making Equipment Working Flow:

Cleaning → water removal → crushing → preparation and cooking → filling → sealing → sterilization

- Cleaning: Clean the peppers that need to be processed and clean the dust on the surface of the peppers to facilitate processing in the next process.

- Water removal: Remove the moisture on the surface of peppers to prevent them from being carried into the next production process.

- Crush: Crush the washed peppers.

- Prepare and cook: Add salt, garlic and other ingredients according to the recipe, cook.

- Filling: The filling process is completed by an automatic filling machine to prevent bacterial contamination.

- Sterilization: The packaged chili sauce enters the sterilization equipment for sterilization. The sterilization time is generally about 10-20 minutes.

Hot Sauce Manufacturing Plant Key Features:

- Automated ingredient mixing: The production line effortlessly blends the perfect combination of spices, peppers, and other ingredients according to your precise recipe, ensuring consistency with every batch.

- Temperature control: Maintaining optimal temperatures during cooking and bottling is essential for preserving flavor and ensuring product safety. This system is equipped with advanced temperature control mechanisms to guarantee the highest quality hot sauce every time.

- Bottle filling and capping: Say goodbye to manual bottling and capping. The hot sauce manufacturing plant handles these tasks with speed and precision, efficiently filling and sealing bottles of various shapes and sizes.

- Customizable settings: Tailor the production process to suit your unique requirements with customizable settings for ingredient ratios, cooking times, and filling speeds.

- Easy maintenance: Designed for ease of maintenance and cleaning, hot sauce making equipment minimizes downtime and maximizes productivity.

Reviews

There are no reviews yet.