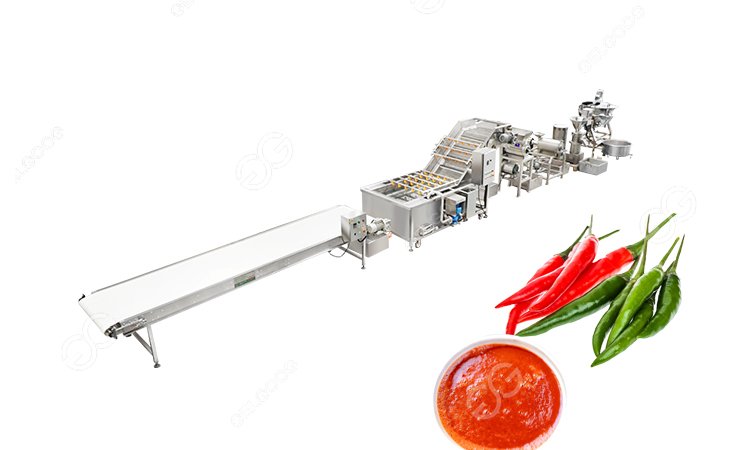

Chili sauce, with its fiery and flavorful profile, has become a staple condiment in kitchens around the world. Have you ever wondered about the intricate process behind the creation of this zesty delight? In this article, we will take you on a fascinating journey through the chili sauce manufacturing process, from the initial cleaning of raw ingredients to the final filling of bottles.

Cleaning:

The manufacturing process of chili sauce begins with the thorough cleaning of raw chili peppers. This step is crucial to ensure the removal of any impurities, dirt, or pesticides that may be present on the peppers. Hygiene is of utmost importance in the food industry, and a rigorous cleaning process sets the foundation for a high-quality chili sauce.

Crushing:

Once the chili peppers are cleaned, they undergo the crushing phase. This step involves breaking down the peppers into smaller pieces to facilitate the subsequent processes. Crushing helps release the essential oils and flavors locked within the peppers, contributing to the distinctive taste of the final chili sauce.

Preheating:

The crushed chili peppers move on to the preheating stage. Preheating serves two primary purposes: Softening the peppers for efficient pulping and initiating the release of flavors. Controlled heat is applied to the crushed peppers, preparing them for the next step in the manufacturing process.

Pulping:

Pulping is a critical stage where the preheated and softened chili peppers are transformed into a pulp. This process involves mechanically breaking down the peppers further, resulting in a smooth and consistent texture. The pulping stage plays a pivotal role in achieving the desired viscosity and texture of the chili sauce.

Concentration:

After pulping, the chili sauce undergoes a concentration process. This step involves reducing the water content in the sauce to enhance its thickness and intensify the flavors. Concentration is typically achieved through controlled heating and evaporation, resulting in a concentrated chili sauce ready for the next phase.

Filling:

The final step in the manufacturing process is filling the chili sauce into bottles or containers. Precision is key during this stage to ensure uniformity and hygiene. Automated filling machines are often employed to achieve accuracy and efficiency. Once filled, the bottles are sealed to preserve the freshness and flavors of the chili sauce.

The journey from raw chili peppers to the delectable chili sauce on your table involves a meticulous manufacturing process. Cleaning, crushing, preheating, pulping, concentration, and filling – each step contributes to the creation of a high-quality product that adds spice to culinary experiences worldwide. If you have any demand of chili sauce processing line to start the chili sauce business, leave message to us.