Description

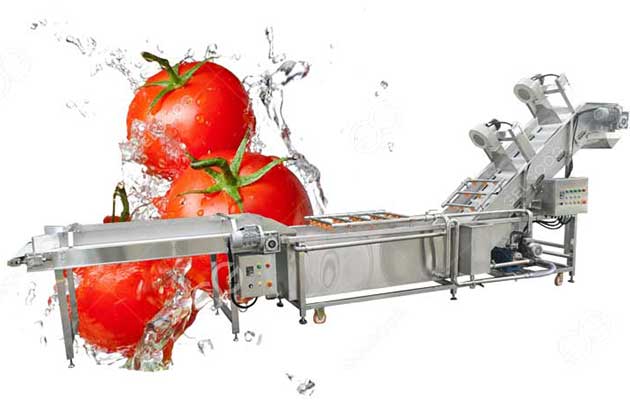

Jackfruit cleaning machine with air drying have a bubble generating device and a high-pressure spray device to make the material in a tumbling state to remove the surface gum of the jackfruit.Before washing, if we add an appropriate amount of salt for jackfruit soaking in the cold water will have a better cleaning effetcs.

Jackfruit cleaning machine uses high-pressure steam bubble water bath cleaning, supplemented by strong water flow to urge the flow. The cleaning ability is large, the cleaning rate is high, and the jackfruit skin is not damaged. After rotating and urging, jackfruit flows to the conveyor belt, and is cleaned by high-pressure water flow on the mesh belt and then transferred to the conveyor belt.

Jackfruit Cleaning Machine Features

1. The main body of the equipment is SUS304 stainless steel, which has good cleaning effect and can maintain the original color of jackfruit.

2. We can customize it according to the user’s respective processing characteristics to meet the process requirements to the greatest extent.

3. The washing machine adopts high-pressure water bubble water bath to clean, without damaging the jackfruit. After spray cleaning, jackfruit is lifted and transported to the next process.

4. The medium water can be filtered and recycled, with high cleaning efficiency, strong practicability and energy saving.

5. We can use it as a stand-alone machine, or we can use it with assembly line operation. We can also add a lifting device according to customer’s requirements.

Jackfruit Washing Machine Advantage

1. The equipment with a circulating water pump and a filter water tank to realize the recycling of cleaning water, save water, and replace with new water according to the actual production situation;

2. The conveyor belt motor of the equipment can realize the function of adjusting the speed change. The cleaned jackfruits are transported through the network chain, automatically fed, automatically discharged, and the conveyor speed of the conveyor belt is adjusted according to the production needs;

3. The equipment with a spray device, which sprays the jackfruits during the transportation to the next process after cleaning to reduce secondary pollution;

Here is oue jackfruit cleaning machine working process in our factory for your reference!!

Jackfruit Cleaning Machine Paremeter

| Item | Washer+Dryer | Chiller |

| Model | XQ3000F | GG-05A |

| Power | Conveyor: 0.75kw Bubble Generator: 2.2kw Water Pump: 0.75kw Blower: 0.75kw*4 |

Compressor: 5HP Water Pump: 0.5HP Fan: 0.18kw*2 Cooling: 15kw |

| Voltage | 415V/50Hz/3Phase | 415V/50Hz/3Phase |

| Machine Material | 304 Stainless steel | Compressor+ Evaporator+ Condenser |

| Conveyor width | 800mm (SUS 304 Chain plate) | ** |

| Water working temperature | 1-4℃ | Normal temperature to 1-4℃ Water flow rate of 100 liters per minute |

| Weight | 460Kg | 170Kg |

| Size | Machine: 3225*1580*1950mm Total Volume: 1360 liters Input height: 868mm Output height: 1000mm Height is customized. |

Machine: 1250*630*1240mm Main plate: 2mm, Sealing plate: 1.5mm |

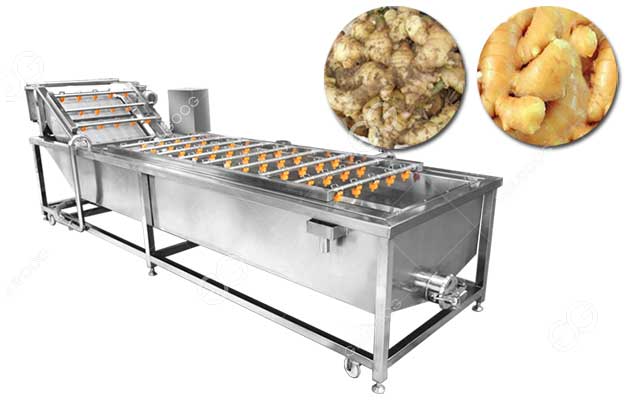

After bubble cleaning, it can also be matched with a hair roller cleaning machine. The jackfruit moves forward on the running brush continuously. The jackfruit rubs with the brush, and the glue adhered to the jackfruit falls off. At the same time, countless high-pressure spray heads spray on the jackfruit. Water scouring can achieve the purpose of efficient cleaning and make the product enter the next process. A waste collection tray can also be installed at the bottom of the machine to prevent sewage, dander, etc. from polluting the ground.

After two cleaning procedures,you can complately clean the hard-to-wash gum on the surface of jackfruit. If you need it, you can also configure an air-drying system.

Jackfruit Air drying equipment features

1. After cleaning, jackfruit has a lot of residual water droplets, and the air dryer effectively removes the water droplets on the jackfruit surface, which improves the degree of production automation.

2. Compared with the traditional jackfruits drying and dewatering method, the air dryer is simple to operate, convenient to use, high in water removal rate (up to 99%), and there is no scale pollution on the surface of the package.

3. Made of high-quality SUS304 stainless steel, frequency conversion speed control, the air dryer runs smoothly, small in size and high in efficiency.

Equipped with an air dryer can quickly remove the excess water on the jackfruit surface, shorten the time, and also facilitate your subsequent packaging or other deep processing.

Reviews

There are no reviews yet.