Description

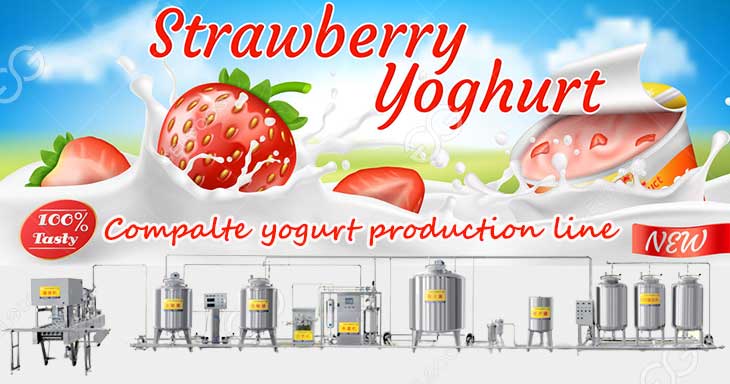

Compalte yogurt production line equipment is specially developed for yogurt processing. Fermented yogurt is also called liquid yogurt. It is slightly thinner and is fermented before filling. It is fermented in the fermentation tank for 6-8 hours, then condensed, scraped and stirred. Just fill it, you can drink it, you can drink it with a straw, it is also a popular yogurt.

Both liquid yogurt and solid yogurt are now deeply loved by consumers. Many dairy processing plants have found this business opportunity and are now beginning to process yogurt one after another. The yogurt consists of a full set of pasteurized milk and yogurt production lines.

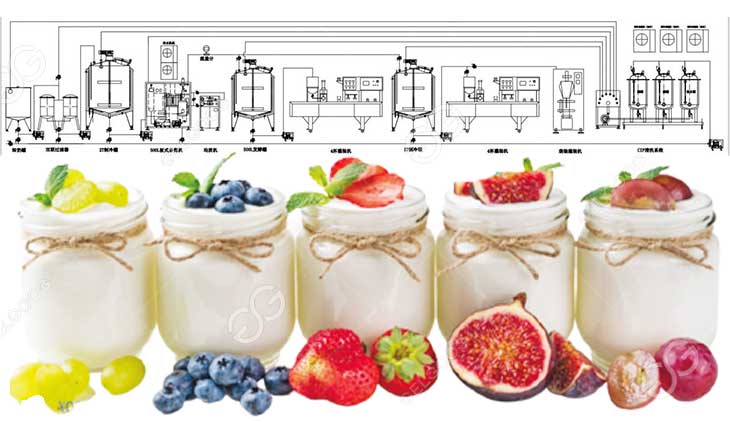

The processing flow of the fermented yogurt production line: milk intake→filtration→raw milk storage→preheating→homogenization→sterilization→fermentation→filling→cip cleaning. The homogenizer is a necessary equipment for making yogurt, and the homogenized milk is processed The yogurt tastes good, and a homogenizer is generally used to make yogurt. The yogurt manufacturing process is as follows:

1. The milk enters the double filter through the pipeline to filter the impurities in the milk.

2. The preheating tank heats the milk, the temperature is about 60 degrees.

3. The milk enters the homogenizer through the pipeline and the milk pump for homogenization (liquid yogurt machine and solid yogurt need to be homogenized, the main advantage of homogenization is that the color of yogurt is relatively white).

4. After the homogenization is completed, it enters the milk sterilization machine through the pipeline and the milk pump for sterilization. The temperature and time of the sterilization tank can be adjusted by itself (the general sterilization temperature is about 85 degrees and the time is 30 minutes).

5. After the sterilization is completed, the compressor is used to cool the milk. The temperature of the pasteurized milk can be automatically adjusted. The fermentation temperature of yogurt is about 42 degrees. Liquid yogurt can be made with a fermentation tank, and solid yogurt can be made with a yogurt machine. Yogurt machines generally use yogurt paper cups, and the fermentation time of yogurt is 8 hours.

6. If the customer can also use the pre-cooling tank as a temperature controller to make liquid yogurt fermentation, after the entire process of the equipment is completed, the equipment’s pre-heating tank can be used as a hot water pipe, and a set of pipes is added to the entire production line And water pump for cleaning equipment

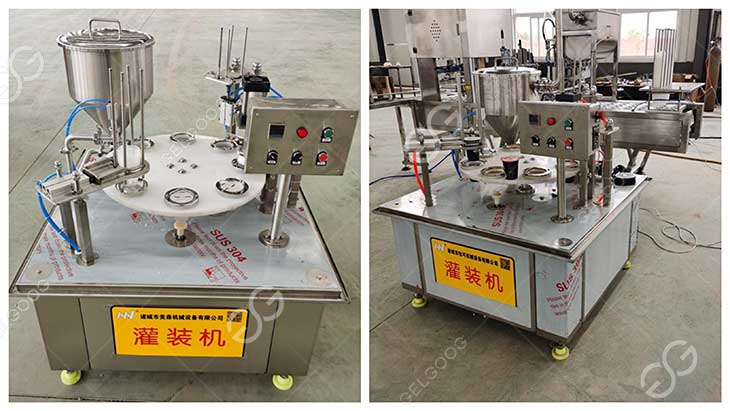

7. Yogurt filling is the last step of the entire production line. It can pack yogurt into cups and then you can sell them in the market. The filling process is automatic, which can save a lot of time and energy, and we provide 3 types of filling machines with different capacities, you can choose according to your needs. In addition, we can customize the size of the yogurt cup for you.

8. We have a special CIP cleaning system, which consists of three stainless steel water tanks with pumps. Water, acid and alkali are stored in these water tanks. The cleaning step is water-alkali-water-acid-water, which can completely clean every part of the yogurt production line without any residue.

The fermented yogurt production line is especially suitable for people who have pastures. They have their own milk source. The quality of the milk source is well controlled. The quality of the milk source is good. The quality of the yogurt made is good. You can build a processing workshop near the pasture or pasture to squeeze it. After the milk comes out, you can continue to process it. The yogurt made is fresh and high in nutrients. Drinking yogurt often helps digestion.

Here is our youtube video of the yogurt milk production line in our factory show for your reference!!

The whole set of equipment of the fermented yogurt production line material is stainless steel. We can customize one ton to dozens of tons per day. We have specialized technicians who can make the flow chart of the equipment on site. You can also give the plan of the design workshop. If you have a pasture ,also want to process yogurt, welcome to leave your inquiry online or visit our company.

Reviews

There are no reviews yet.