Description

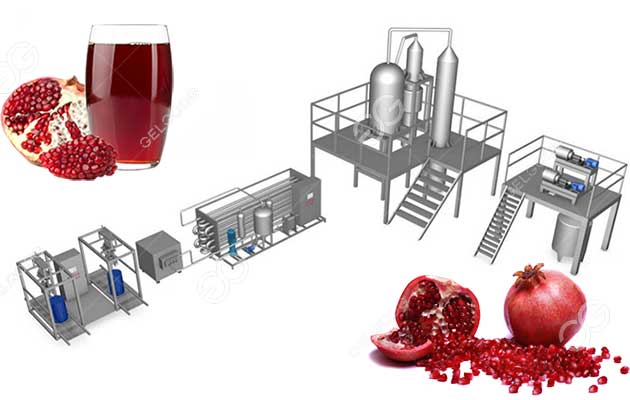

The pomegranate juice processing line uses premium pomegranates as raw materials, uses scientific peeling methods, juice extraction techniques, and aseptic packaging technology to process the pomegranate juice with a concentration of 64-66°Brix and a total acid of 0.5-5.0%.

Pomegranate Juice Processing Line Technical Parameter

Ingredients: pomegranate

Product: NFC pomegranate juice

Capacity: 1T pomegranates per hour (250-400kg/h finished product)

Customer Process: Juicing, Sterilization, Filling

How to Make Pomegranate Juice from Pomegranate

The processing of pomegranate juice mainly includes: picking→bubble cleaning→lifting→peeling→transporting→juicing→low tank→pump→rotating screen→low tank→degassing→sterilization→BIB filling.

【Raw Material Selection】

Choose pomegranate that are fully ripe, fresh, good flavor, rich in juice, and free of pests and diseases, and remove the pomegranate with pests, diseases, or rotten parts. We should pick out the not enough mature pomegranate.

【Raw material pretreatment】

1. Cleaning. After selecting the pomegranates, wash and remove the hair with clean water, rinse them in 1% hydrochloric acid solution or detergent solution to remove residual pesticides, rinse in clean water, and seed.

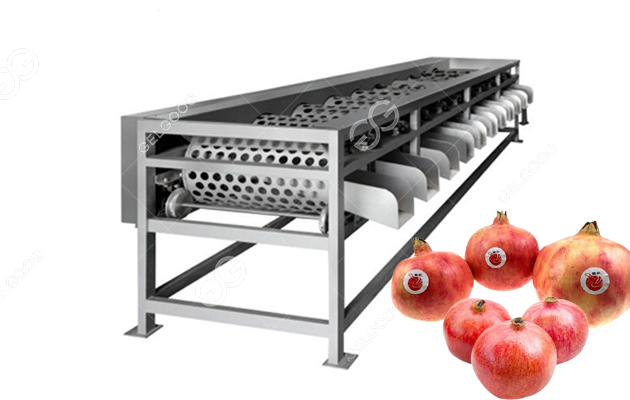

2. Peel and take pellets. Use a pomegranate peeling machine to remove the pomegranate skin and keep the whole pomegranate seeds.

3. Immersion protection. In order to protection the color ,we soak the pomegranate seed in a mixed solution of 0.1% iso-ascorbic acid and citric acid.

【Heating & pulping】

The pomegrante seeds are heated at 90-95°C for 3-5 minutes to promote softening, and be beaten by a pomegranate juice making machine with a diameter of 0.5 mm to remove the core.

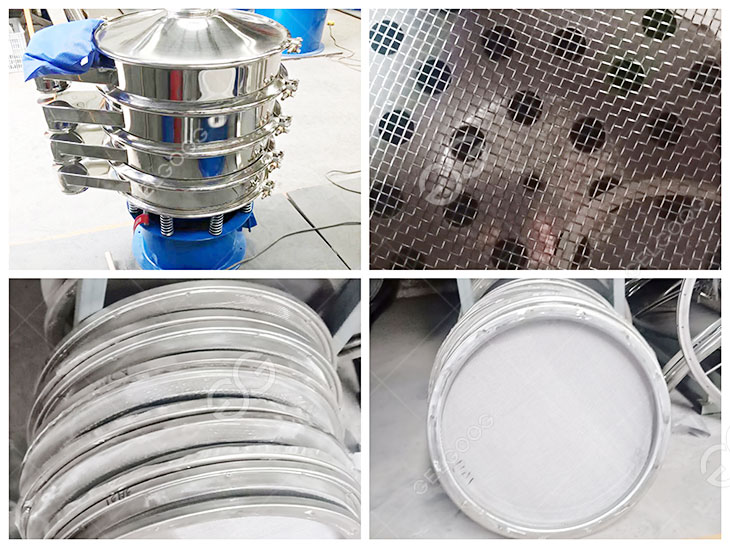

【Filter】

The rotary vibrating sieve filters the small meat particles and other impurities in the juice to increase the taste of the juice.

【Homogeneous】

Homogenization is to split the suspended pulp particles of pomegranate juice into smaller particles and evenly disperse them in the pomegranate juice to increase the stability of the pomegranate juice and prevent delamination. Generally, homogenizers of 130-160 kg/cm² are used in production.

【Degassing】

The fruit enters oxygen, nitrogen, carbon dioxide and other gases during juice extraction. Oxygen can cause the oxidation of vitamin C and pigments and corrode the tinplate cans, so degassing is necessary. The pomegranate juice is put into a vacuum container, and the pomegranate juice is sprayed out in a misty state to degas.

【Sterilization and canning】

Pomegranate juice is heated to 95°C and maintained for 1 minute. It is immediately filled into cans while hot, and packed in BIB sterile box-in-bags.

【Sealed cooling】

Tighten the lid and turn the box upside down for 1 minute. After sealing,we will storage it , when it cool down in section to about 38°C.The finished pomegranate juice of qualified quality is pink or yellowish brown, and it is allowed to be dark red; the juice is uniformly turbid, and particles precipitate after long-term standing;

Advantages Of Pomegranate Juice Production Line

1. The automatic pomegranate seed extractor adopts the method of imitating manual peeling, and we can control the whole process automatically.

Thr poemgranate peeling machine can speparate pomegranate seeds and the pomegranate skin completely , and the pomegranate seeds preserved intact, without damage, and we need to wash the seeds with water.

2. The combined equipment adopts three-stage sterilization method, aseptic filling machine and BIB bag-in-box dispenser for low-temperature filling of freshly squeezed pomegranate juice, aseptic packaging.

Maximum retention of the nutrient content of the original fruit, the product does not add any preservatives ,we can store and transport them at room temperature.

3. Long storage time. You can store the pomegranate juice products in BIB boxes for 12 months at room temperature.

We packaging 200 kg of freshly squeezed pomegranate juice in aluminum foil sterile bags and packaging in large iron drums for external use.

We store them at room temperature for 18 months.

Pomegranate Juice Processing Line Features

1. The material of the whole line is 304 stainless steel to ensure the cleanliness of the production process;

2. Fully automatic operation process, saving manpower and material resources;

3. The pomegranate juice retain the original flavor and nutrients of pomegranate.

Reviews

There are no reviews yet.